Versatile Compatibility: Suitable for all standard and irregular shapes and sizes of tablets, capsules, and more.

High Counting Accuracy: The machine achieves counting differences of less than 1‰, ensuring precise counting and filling.

Smooth Operation and Low Noise: It operates smoothly with minimal noise, providing a conducive working environment.

Full-Set Protective Devices: The machine is equipped with a comprehensive set of protective devices, ensuring stable and reliable operation.

Touch Screen Control System: Easy-to-use touch screen control system enables convenient operation and control.

Simple Operator Control: The machine is designed with straightforward operator controls for ease of use.

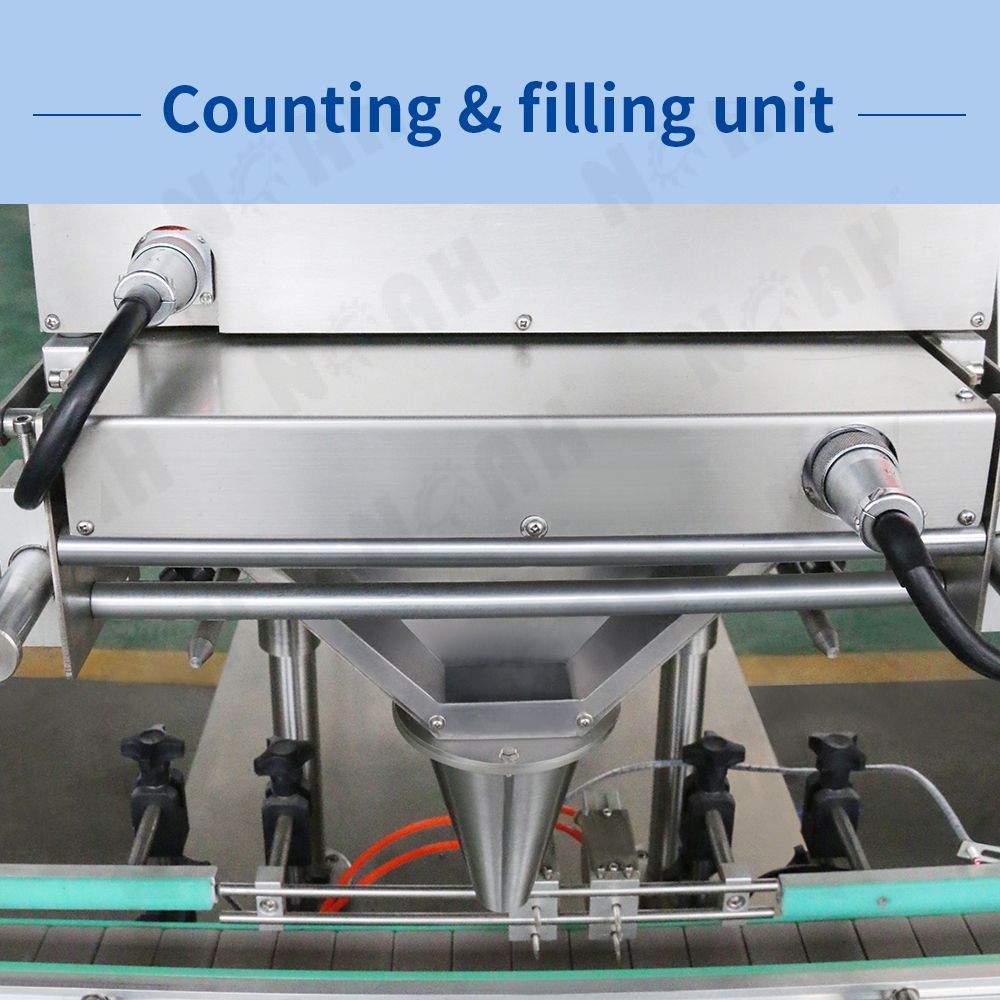

Stainless Steel Frame: Constructed with a stainless steel frame, the machine offers durability and compliance with industry standards.

Download

Download