Investment Return Analysis for DPH-250 Flat-plate Automatic Blister Packing Machine:

Investing in the DPH-250 Flat-plate Automatic Blister Packing Machine offers promising growth prospects and potential investment returns. Here's an analysis of the investment return based on key factors:

Growing Pharmaceutical Packaging Market: The pharmaceutical packaging market is expanding globally, driven by the increasing demand for safe and secure packaging solutions. The DPH-250 machine caters to this demand by providing efficient and reliable blister packaging for solid dosage forms. The growing pharmaceutical market presents significant growth opportunities for the machine, positively impacting investment returns.

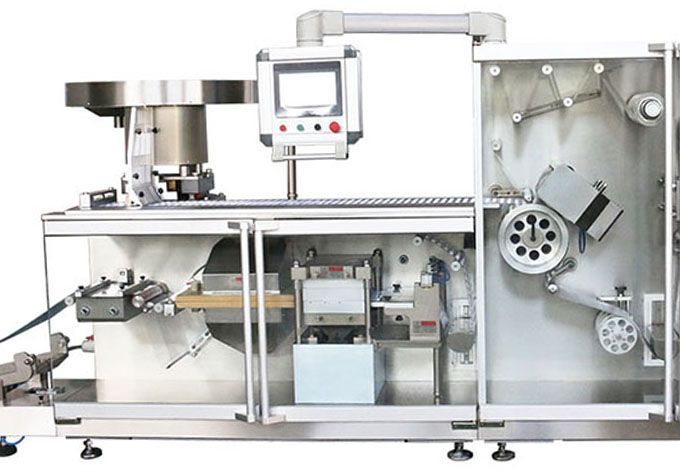

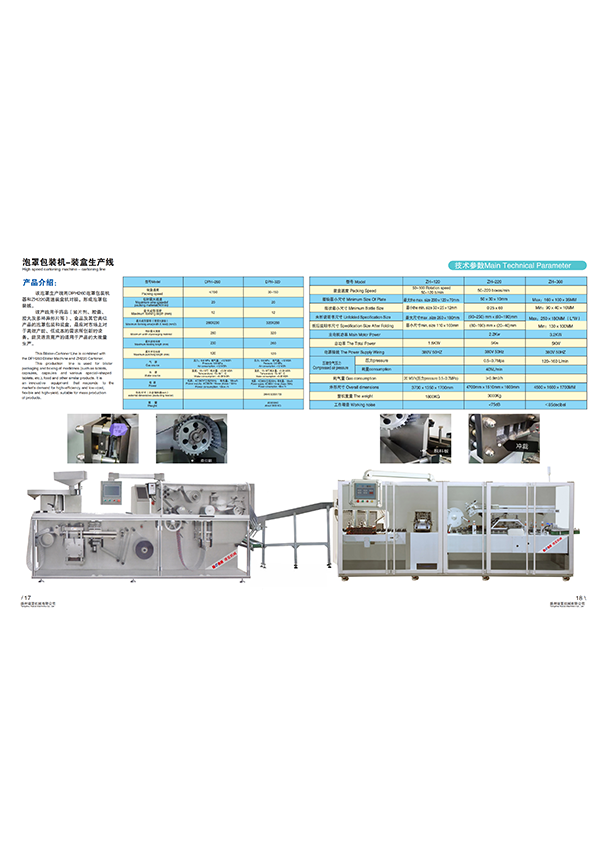

Automation and Efficiency: The DPH-250 machine is an automatic blister packing solution that offers high efficiency and productivity. With its flat-plate design and advanced automation features, it enables fast and accurate packaging, reducing labor costs and improving operational efficiency. The machine's ability to handle high volumes of production contributes to higher throughput and optimized profitability, positively impacting investment returns.

Versatility and Customization: The DPH-250 machine offers versatility in packaging various solid dosage forms, including tablets, capsules, and pills. It provides customization options for blister design and layout, allowing for flexibility to meet specific product requirements. This versatility and customization capability enhance market penetration and customer satisfaction, positively impacting investment returns.

Packaging Quality and Compliance: The DPH-250 machine ensures the quality and integrity of blister packaging. It incorporates precise temperature and pressure control, ensuring airtight and tamper-evident packaging. The machine complies with regulatory standards, such as Good Manufacturing Practices (GMP) and quality control requirements, ensuring adherence to industry regulations. Its ability to maintain product integrity and meet quality standards enhances market demand, positively impacting investment returns.

Cost Savings and Operational Efficiency: The DPH-250 machine offers cost-saving benefits through reduced labor requirements and increased production efficiency. By automating the blister packaging process, it minimizes human errors and improves overall operational efficiency. The machine's ability to optimize resource utilization, reduce waste, and streamline production contributes to improved profitability and investment returns.

Integration and Compatibility: The DPH-250 machine can be seamlessly integrated into existing pharmaceutical production lines. Its compatibility with upstream and downstream equipment, such as blister feeders and cartoning machines, streamlines the packaging process and enhances overall operational efficiency. This integration capability improves productivity, reduces downtime, and contributes to the investment return.

Technological Advancements and Upgrades: The packaging industry is continually evolving with advancements in automation, software integration, and quality control. The DPH-250 machine can leverage these technological advancements to stay competitive and meet evolving customer needs. Regular upgrades and improvements in the machine's capabilities ensure its long-term value and optimize investment returns.

After-sales Service and Support: Reliable after-sales service and support are crucial for maximizing investment returns. Manufacturers typically provide installation assistance, training, and ongoing technical support for the DPH-250 machine. A robust support system ensures smooth operation, minimizes downtime, and enhances customer satisfaction, contributing to the overall investment return.

Return on Investment (ROI): The DPH-250 Flat-plate Automatic Blister Packing Machine has the potential to generate a significant return on investment. Factors such as market demand, pricing strategy, operational costs, maintenance, and market penetration will influence the exact ROI. Conducting a comprehensive cost-benefit analysis, considering these factors and projecting sales and operational expenses, will provide valuable insights for optimizing the investment return.

Competitive Advantage: By investing in the DPH-250 machine, businesses can gain a competitive advantage in the pharmaceutical packaging market. Its automation capabilities, versatility, packaging quality, compliance with regulations, and integration features position the investment as a strategic move to differentiate from competitors, capture a larger market share, and achieve higher investment returns.

To further enhance the investment return, it is advisable to engage with industry experts, pharmaceutical manufacturers, and conduct thorough market research to understand market dynamics, competitive landscape, and emerging trends in the pharmaceutical packaging industry. Additionally, staying updated with regulatory requirements and maintaining compliance will contribute to the long-term success and profitability of the investment.

Download

Download