EYH 2D Movement Mixer is engineered for large-scale industrial blending across diverse sectors, including:

Pharmaceuticals: Mixing powders, granules, and active ingredients under GMP-compliant conditions.

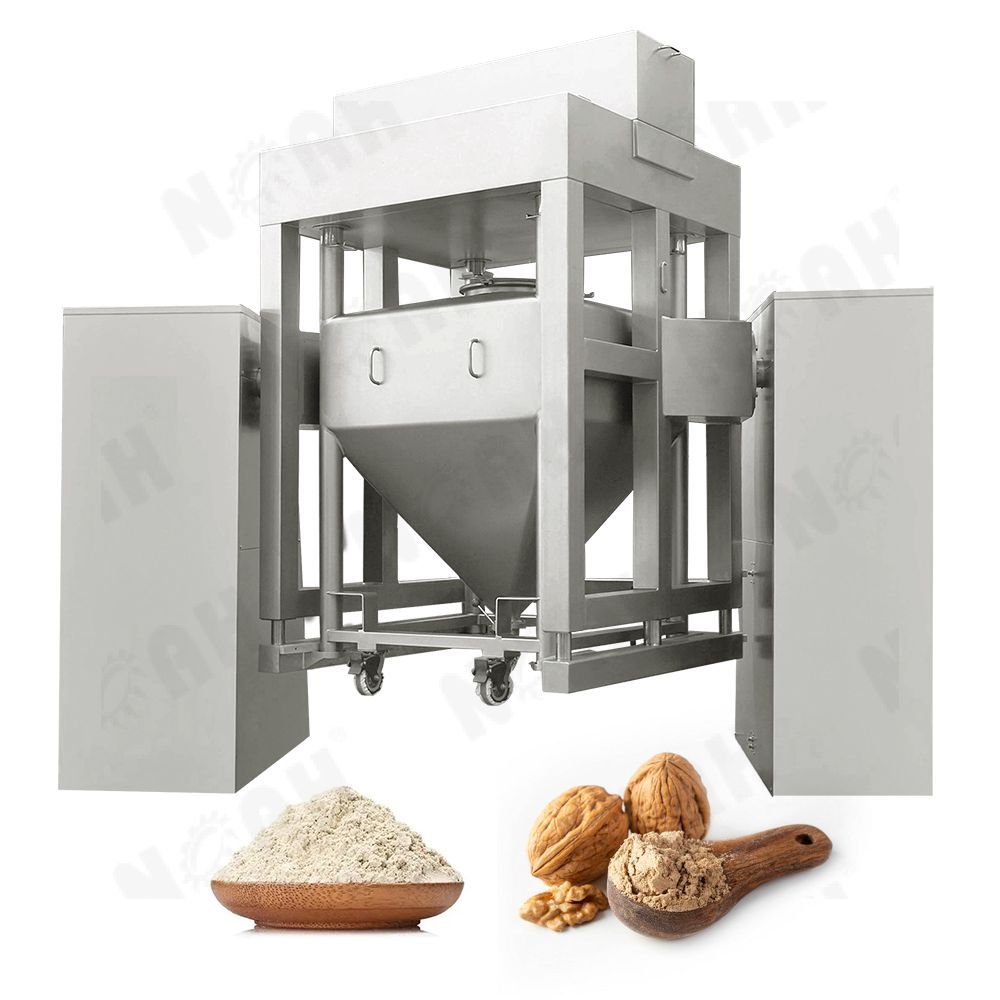

Food Processing: Blending spices, additives, and dry ingredients with hygiene-focused design.

Chemicals & Fertilizers: Homogenizing fertilizers, pesticides, and chemical compounds efficiently.

Dyestuffs & Pigments: Ensuring uniform color distribution in dye powders.

Animal Feed: Mixing nutritional additives and feed components for consistency.

High-Volume Requirements: Ideal for batches ranging from 1,000 to 12,000 liters.

Download

Download