The WLDH Series Horizontal Ribbon Mixer is specifically designed for the mixing of viscous or adhesive powder materials. It is also suitable for mixing powders that require the addition of liquids or paste materials. This mixer is particularly useful in cases where a large output is required, and frequent material variety changes are not necessary. However, it should be noted that cleaning can be challenging when working with viscous materials.

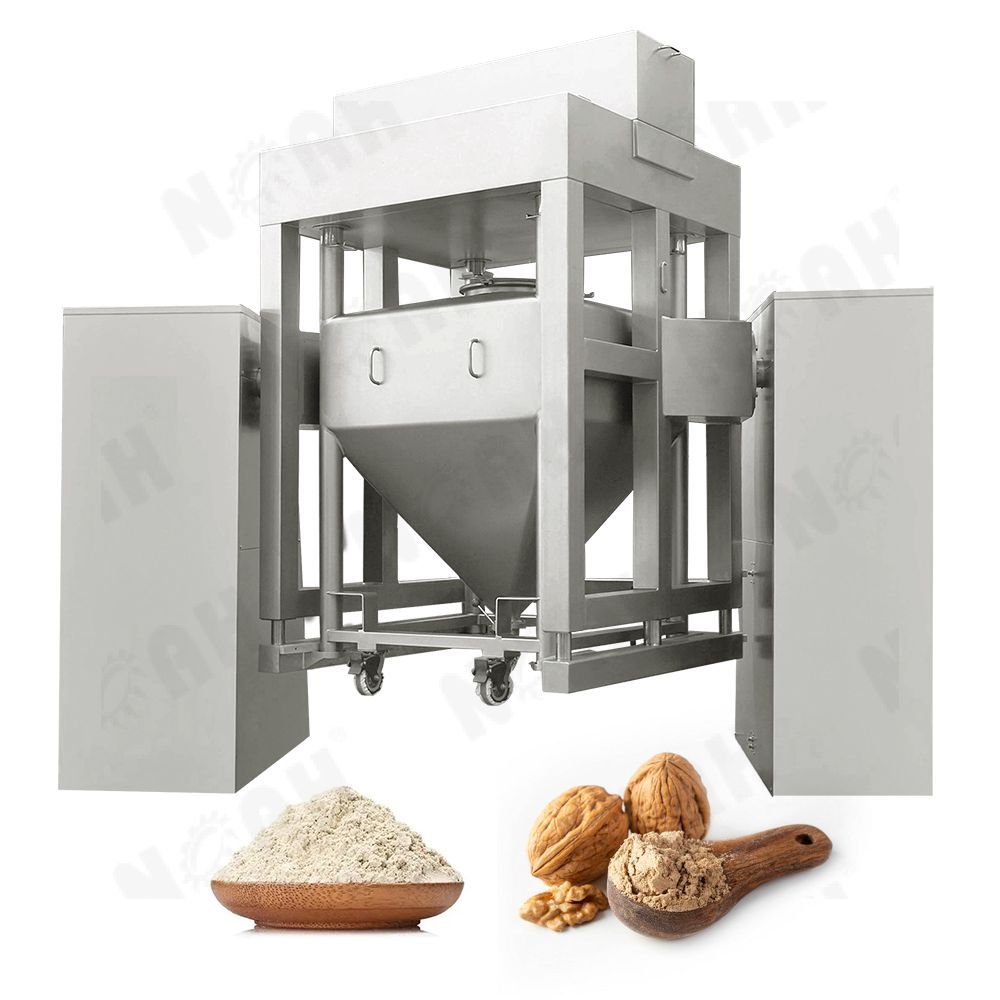

WLDH Series Horizontal Ribbon Mixer

Discover the perfect blend of efficiency and versatility with our powder mixer, ensuring homogeneous mixing of powders for a wide range of industries and applications.

Download

Download