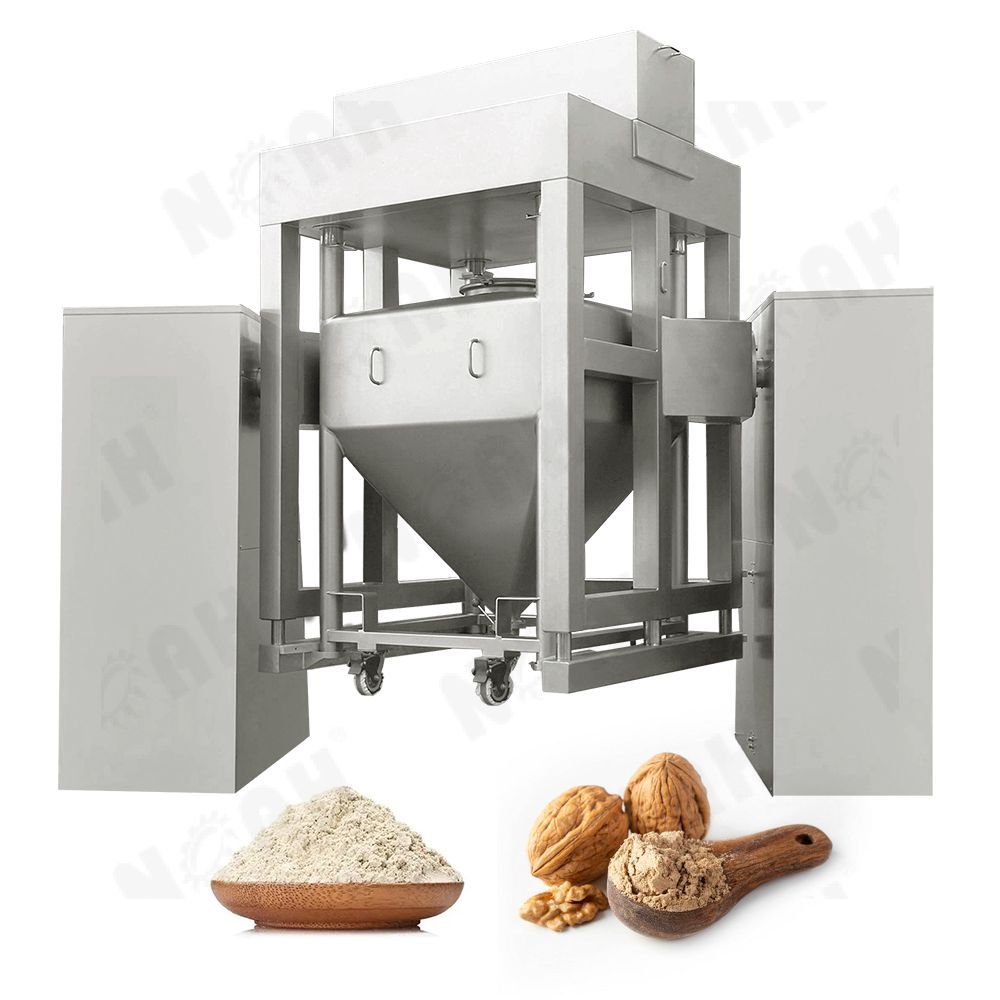

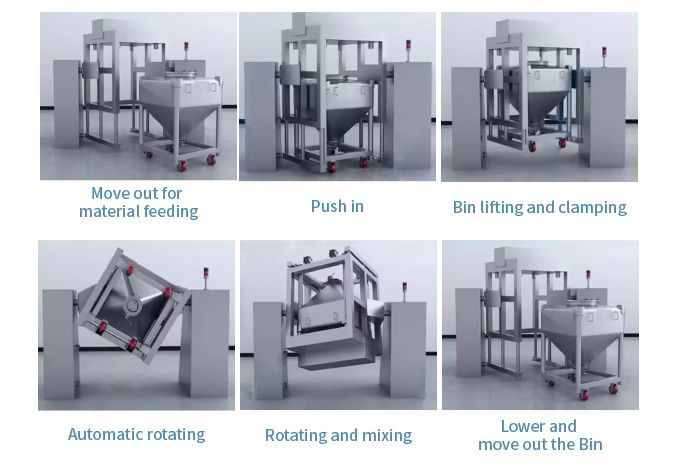

The HTD Series Lifting Bin Blender is primarily used for powder and granules mixing applications. It finds extensive use in pharmaceutical factories and is also suitable for chemical and light industries requiring general mixing.

HTD Series Lifting Bin Blender

Discover the perfect blend of efficiency and versatility with our powder mixer, ensuring homogeneous mixing of powders for a wide range of industries and applications.

Download

Download