Enhancing Pharmaceutical Efficiency with a Comprehensive Tablet & Capsule Counting Line

In the pharmaceutical industry, precision and efficiency are crucial factors in the manufacturing and packaging of tablets and capsules. A Tablet & Capsule Counting Line is a comprehensive solution designed to streamline the counting, filling, and packaging processes, ensuring accuracy and speed in pharmaceutical operations.

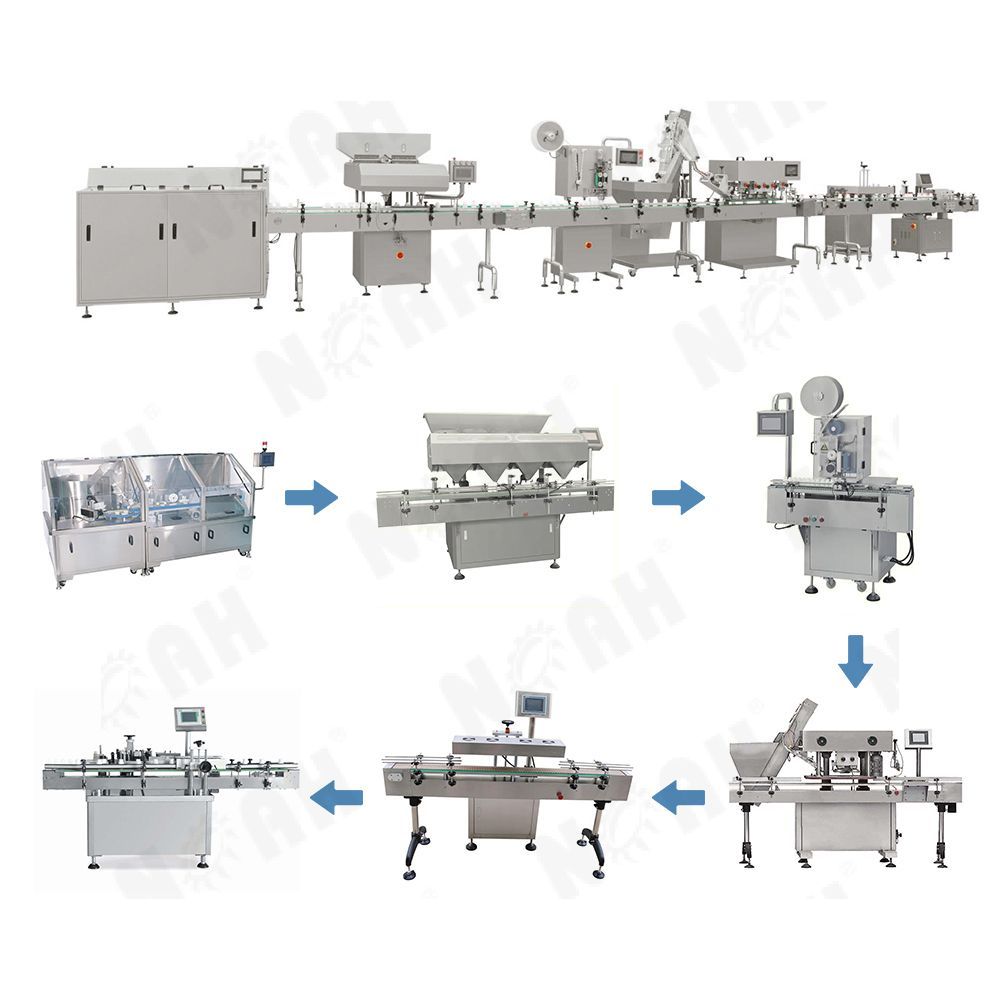

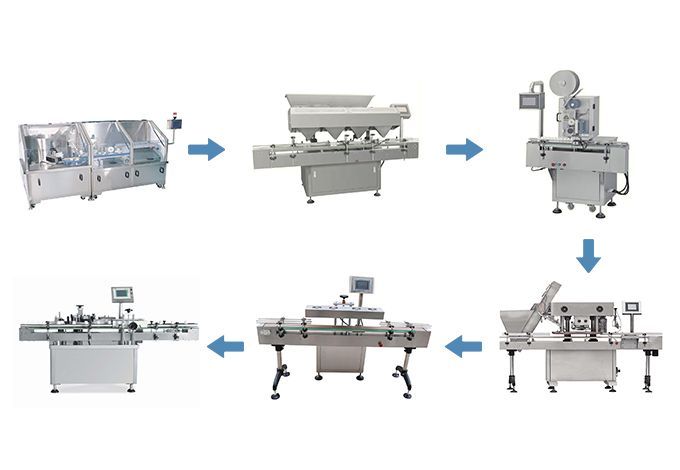

Tablet & Capsule Counting Line Overview

A Tablet & Capsule Counting Line consists of interconnected equipment and machinery that work in harmony to automate the counting and filling of tablets and capsules. From initial counting to bottling and packaging, this integrated line optimizes production efficiency and accuracy, minimizing errors and maximizing output.

Key Components of a Tablet & Capsule Counting Line

Counting Machine: A high-speed counting machine accurately counts tablets and capsules, ensuring precise dosing for each product batch.

Conveyor System: Conveyor belts transport counted tablets and capsules to the next stage of the packaging process seamlessly.

Bottling Equipment: Automated bottling machines efficiently fill bottles with the correct quantity of tablets or capsules, ready for labeling and distribution.

Capping and Sealing Machines: These machines ensure the bottles are securely sealed, maintaining product integrity and safety.

Benefits of a Tablet & Capsule Counting Line

Increased Efficiency: Automation reduces manual labor and speeds up the production process.

Accuracy: Precise counting and filling minimize errors and ensure consistent product quality.

Flexibility: These lines can be customized to accommodate various tablet and capsule sizes and shapes.

Cost-Effectiveness: Streamlined operations result in cost savings over time.

Download

Download