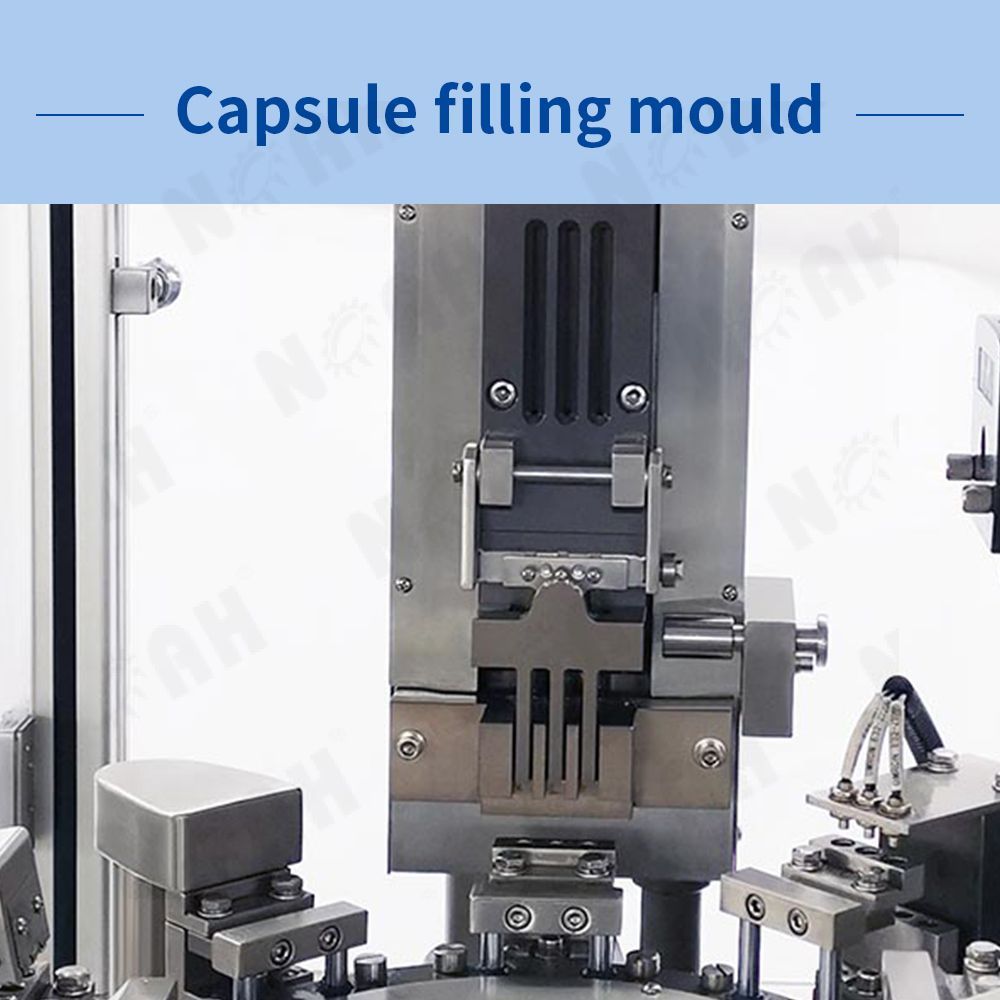

NJP-300C/600C Automatic Hard Capsule Liquid Filling and Sealing Machine is primarily used in the pharmaceutical industry and health food factories. It is specifically designed for filling hard capsules with liquid formulations such as solutions, mixed suspensions, micro-milks, or hot solutions. The machine is widely applied in the production of various preparation products, offering an innovative administration method and addressing medication-related challenges. It is particularly suitable for pharmaceutical companies and health food factories involved in the development of products containing high-active drugs and enabled drugs.

NJP-300C/600C Automatic Hard Capsule Liquid Filling And Sealing Machine

Discover the perfect solution for efficient and precise capsule filling with our top-of-the-line capsule-filling machine.

Download

Download