RJN Series Softgel Encapsulation Machine Line finds extensive application in the production of softgel capsules. It is widely used in the fields of medicine, health products, cosmetics, and game-color balls. Manufacturers in these industries rely on this machine to efficiently encapsulate oils, mixing suspensions, and pasty masses into softgel capsules of different specifications, meeting the diverse needs of their customers.

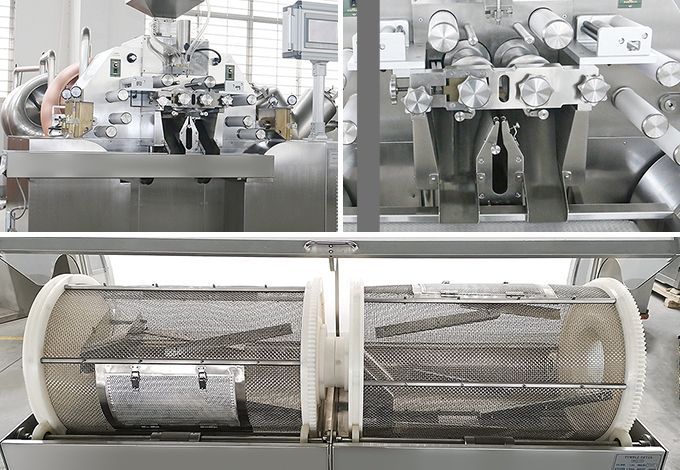

RJN Series Softgel Encapsulation Machine Line

Discover the perfect solution for efficient and precise capsule filling with our top-of-the-line capsule-filling machine.

Download

Download