Revolutionizing Capsule Production with Advanced Filling and Sealing Machines

In the pharmaceutical and nutraceutical industries, precision and efficiency are paramount in the manufacturing of capsules. Capsule liquid filling and sealing machines, along with capsule filling machines, have emerged as indispensable tools that streamline the production process, ensuring accuracy and quality in capsule manufacturing operations.

Capsule Liquid Filling and Sealing Machine

A capsule liquid filling and sealing machine is a sophisticated piece of equipment designed to automate the process of filling capsules with liquid formulations and securely sealing them. These machines utilize advanced technology to precisely dispense liquid contents into capsules, ensuring consistency and quality in the final product.

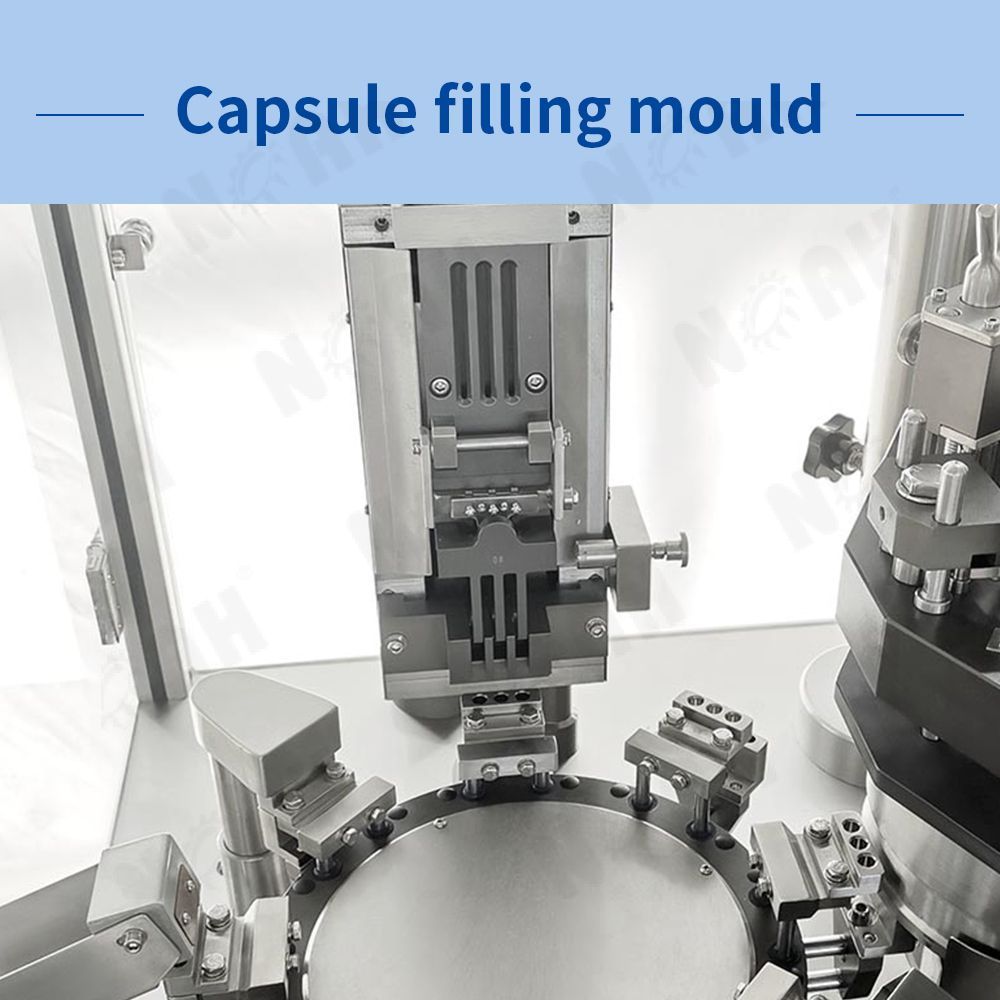

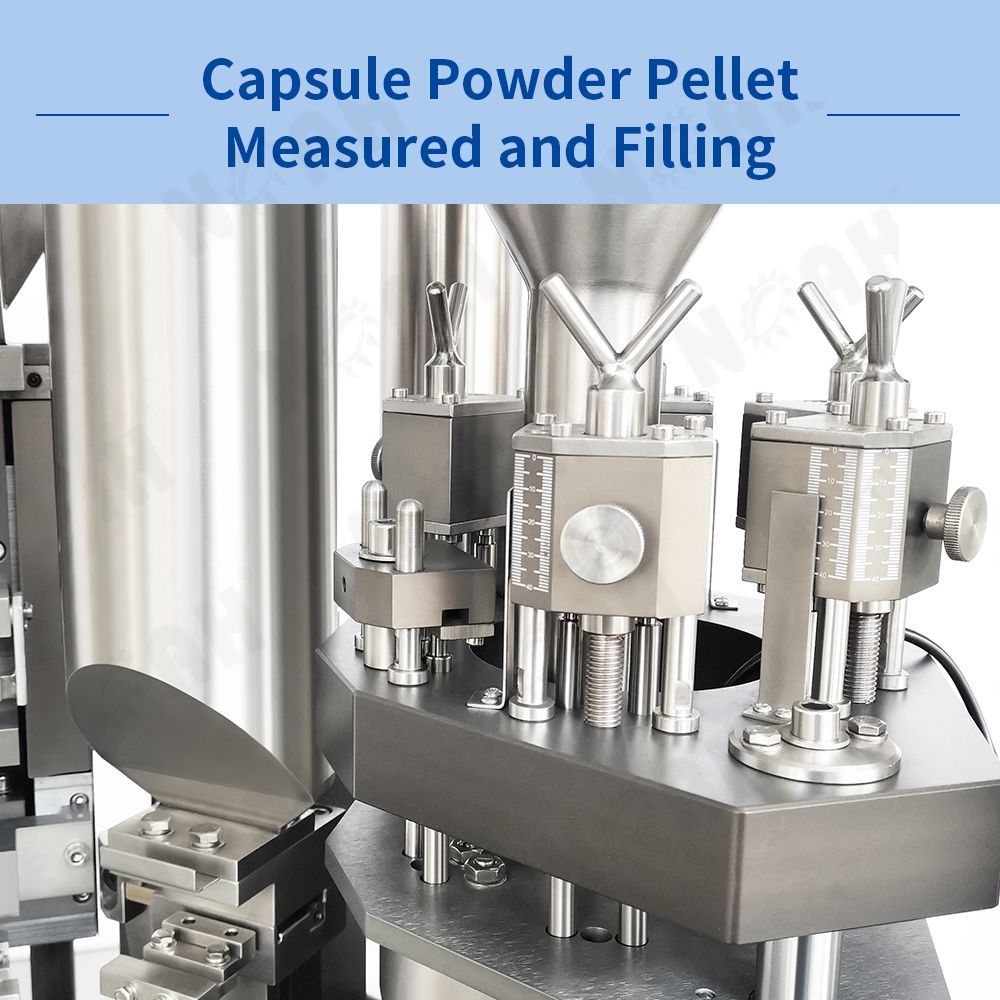

Capsule Filling Machine

Capsule filling machines are essential in the production of solid dosage forms encapsulated within gelatin or vegetarian capsules. These machines efficiently fill capsules with powders, granules, or pellets, providing a precise and uniform dosage in each capsule. By automating this process, capsule filling machines enhance productivity and reduce the risk of errors associated with manual filling.

Key Features of Capsule Filling and Sealing Machines

Precision Filling: Ensures accurate dosing of liquid formulations or solid materials into capsules, maintaining product quality and consistency.

Sealing Capabilities: Securely seals capsules to prevent leakage and maintain product integrity during storage and transportation.

Versatility: Capable of handling a wide range of capsule sizes and formulations, offering flexibility in production.

Automation: Streamlines the manufacturing process, reducing labor costs and increasing production efficiency.

Download

Download