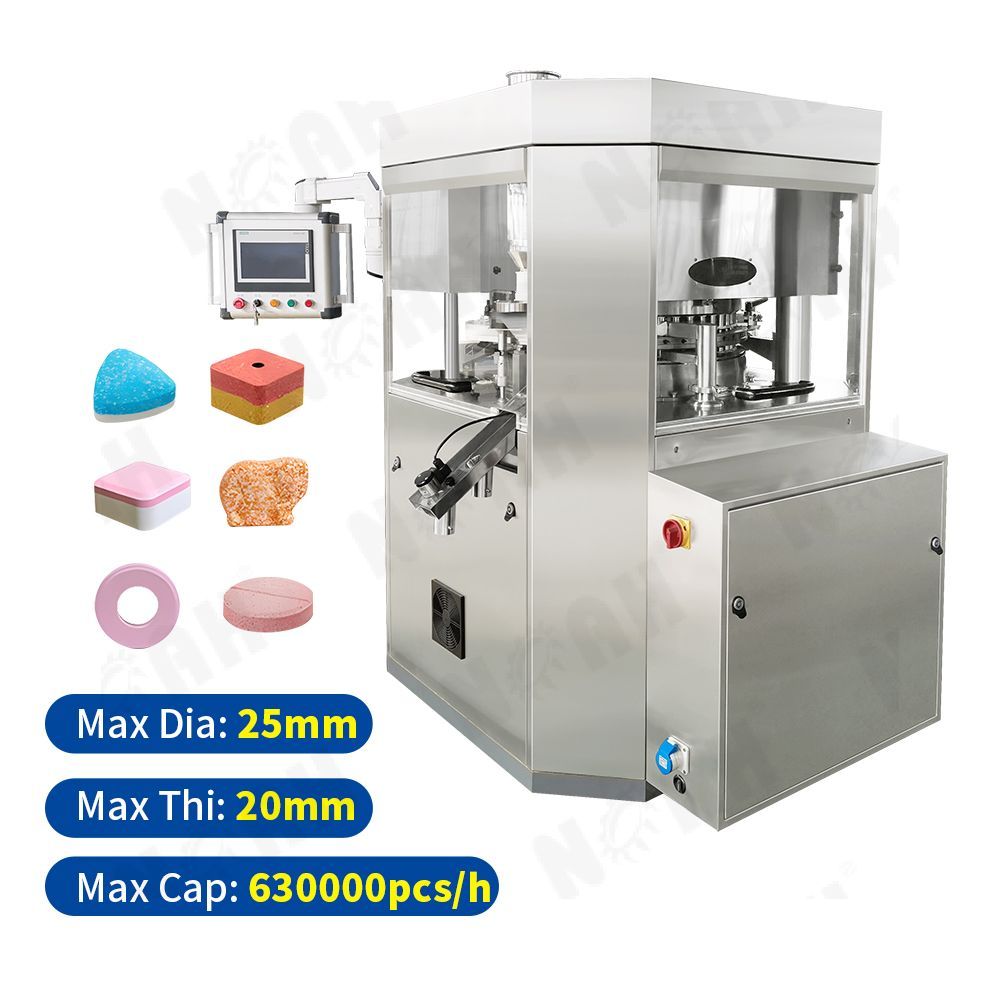

The ZPW21 Rotary Tablet Press Machine is specifically designed to produce tablets from a variety of granular materials. It can create round tablets, as well as tablets with different geometrical shapes, double-layered tablets, and annular tablets. The machine is equipped with 21 sets of movable punches and dies, allowing for the pressing of 21 tablets per revolution of the turret.

The depth of the filling material and the thickness of the tablets can be easily adjusted during operation. Tablet pressing pressure is controlled by a hydraulic drive system, and a pressure gauge is included to display the pressure value. To ensure the safety of the machine, an overload protection unit is integrated to prevent damage to the punches and apparatus in case of overload.

The ZPW21A and ZPW21B models are improved versions of the ZPW21, designed to meet GMP standards. The pressing area of these models is sealed with four polymethyl methacrylate doors, providing isolation from the outside environment. Additionally, parts that come into contact with the material are made of stainless steel or have a specially treated surface to prevent contamination and ensure

Download

Download