The DPB-260/320 Flat-plate Automatic Blister Packing Machine is specifically designed for the pharmaceutical industry, where it efficiently packages capsules, tablets, and honey pills. In the food industry, it is ideal for packaging milk tablets, candies, chocolates, and other similar products. Additionally, it finds applications in the electronics and hardware industries for packaging injectors, syringes, pins, small components, and more. Its versatile design allows it to handle various shapes and types of blister packs, meeting the diverse packaging needs of different industries.

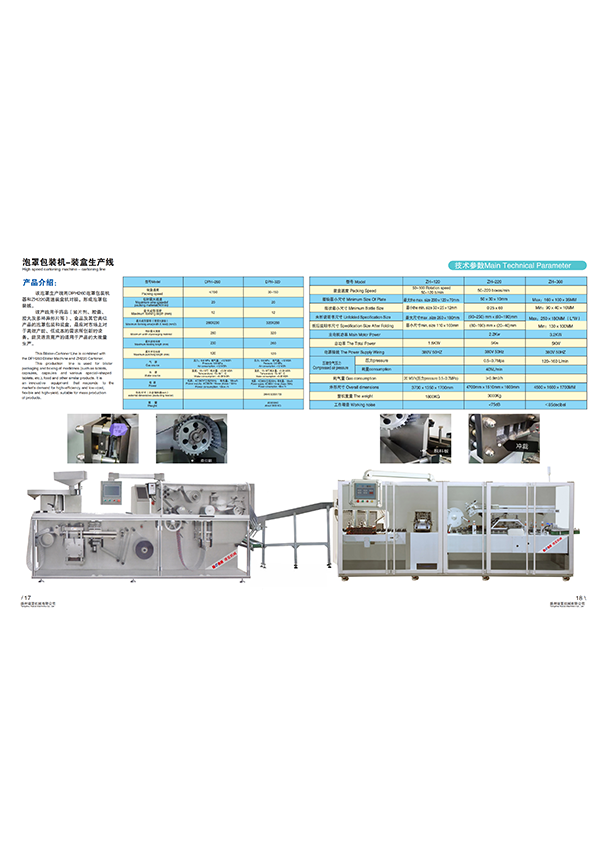

DPB-260/320 Flat-plate Automatic Blister Packing Machine

Experience seamless and efficient packaging with our high-performance blister packing machine, delivering secure and professional packaging solutions for a wide range of products.

Download

Download