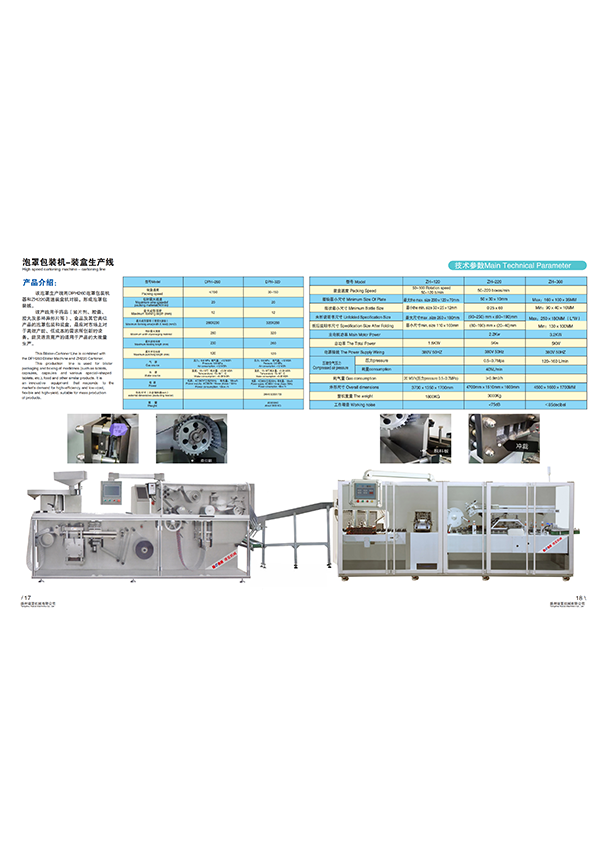

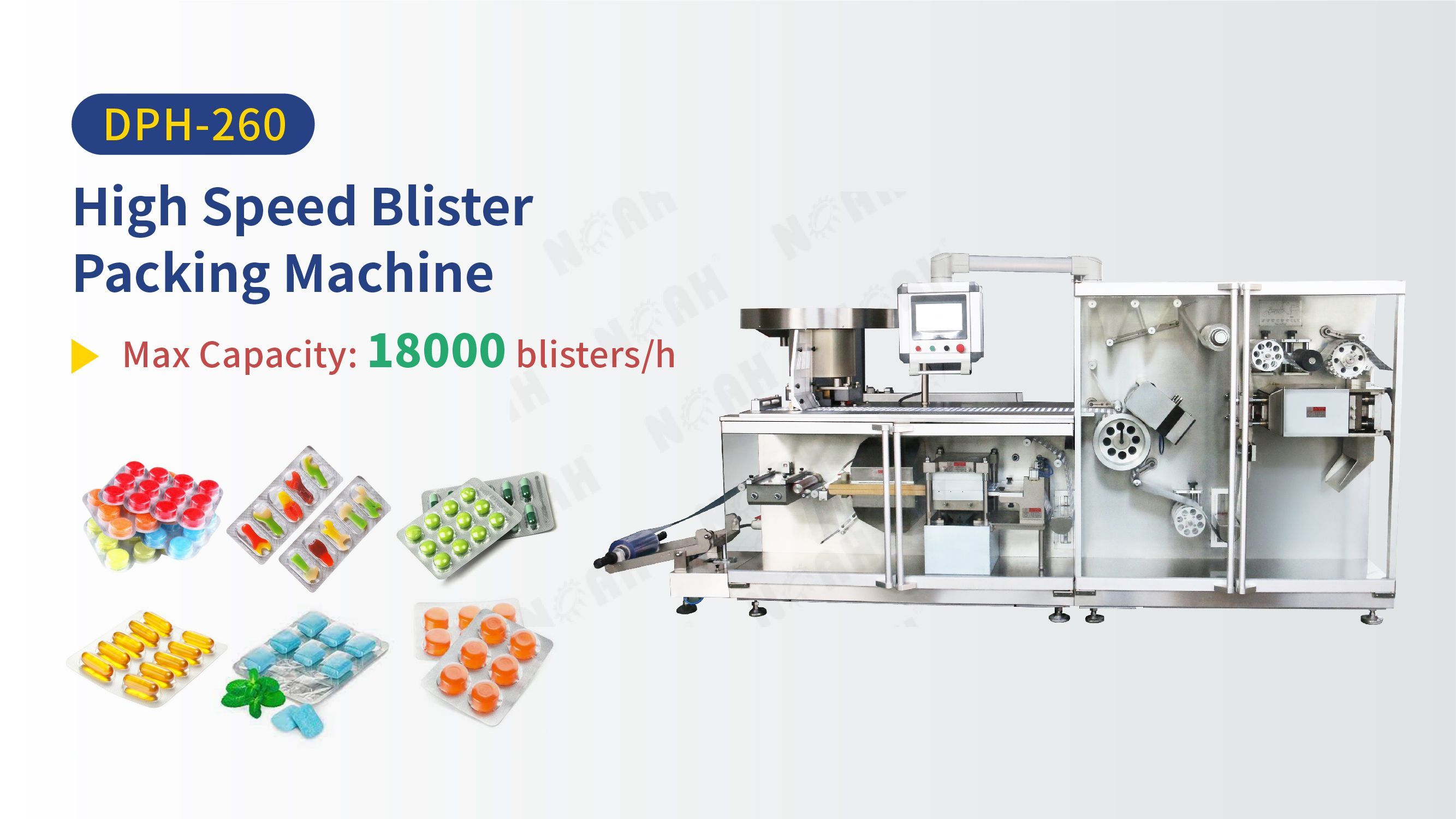

The DPH-260 High Speed Blister Packing Machine is specifically designed for the pharmaceutical industry. It is used for high-speed packaging of various pharmaceutical products, including tablets, capsules, and other solid dosage forms. This machine is ideal for pharmaceutical manufacturers seeking automated and efficient packaging solutions to improve production efficiency while adhering to strict quality standards.

DPH-260 High Speed Blister Packing Machine

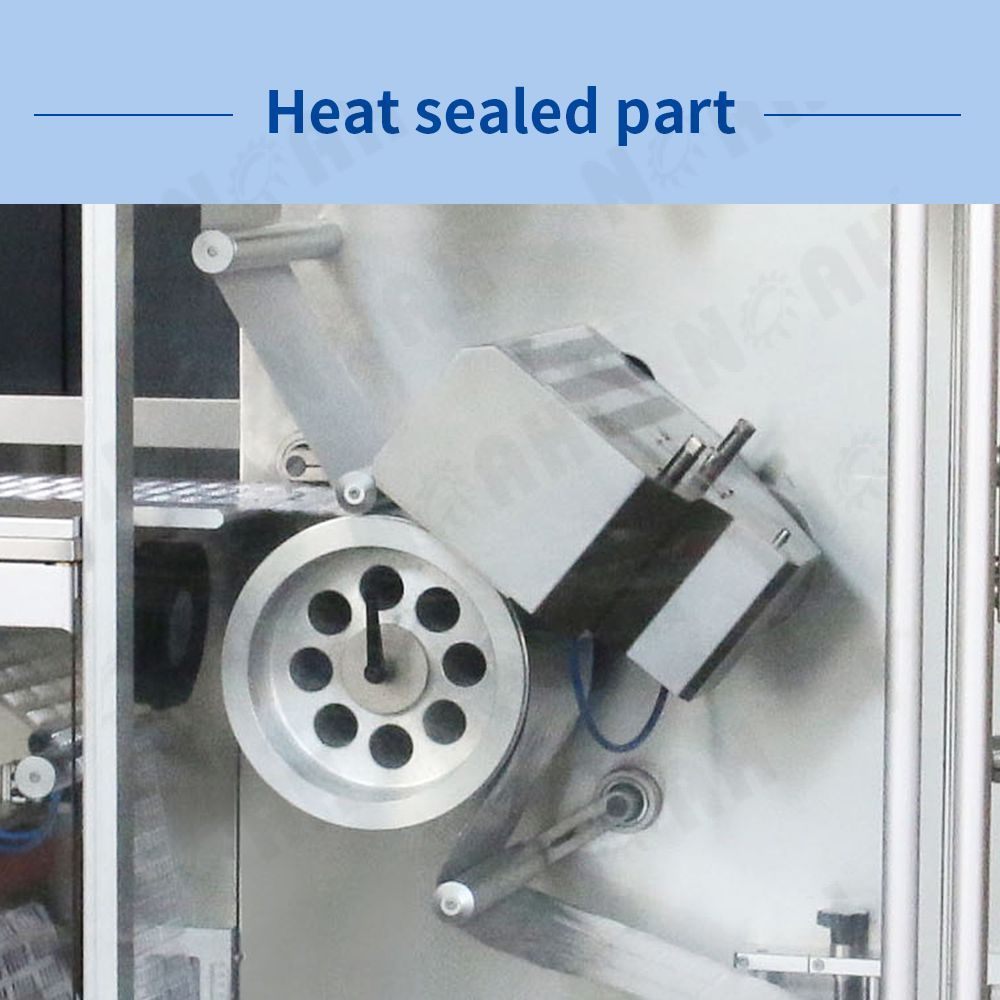

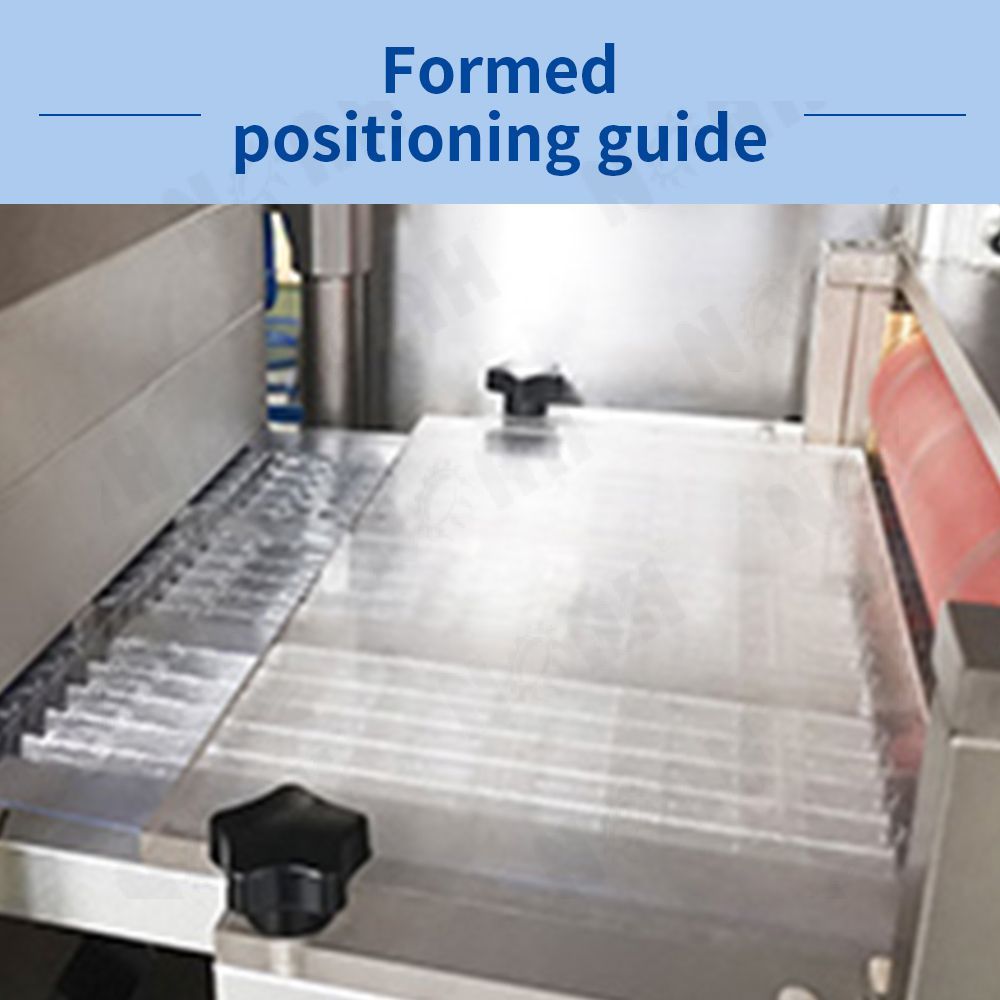

Experience seamless and efficient packaging with our high-performance blister packing machine, delivering secure and professional packaging solutions for a wide range of products.

Download

Download