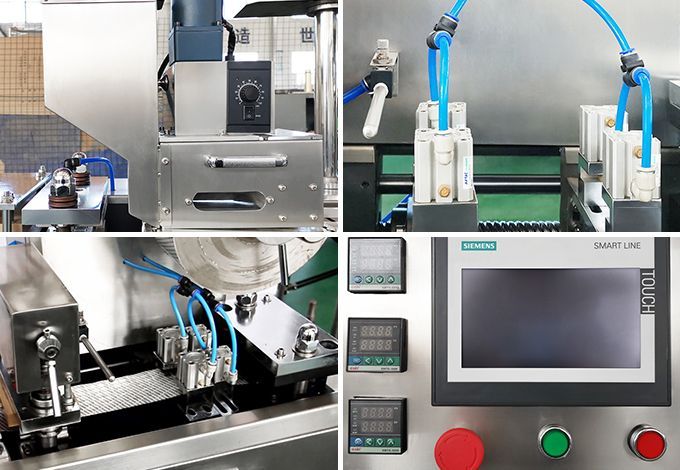

The DPB-100 Flat-plate Blister Packing Machine is specifically designed for usage in hospital dosage rooms, laboratory institutes, healthcare product facilities, and medium-small pharmacy factories. Its compact size, ease of operation, and adjustable stroke make it ideal for these environments. This machine is used to produce a wide range of products in small quantities, meeting the diverse packaging needs of pharmaceuticals, laboratory samples, health care products, and more.

DPB-100 Flat-plate Blister Packing Machine

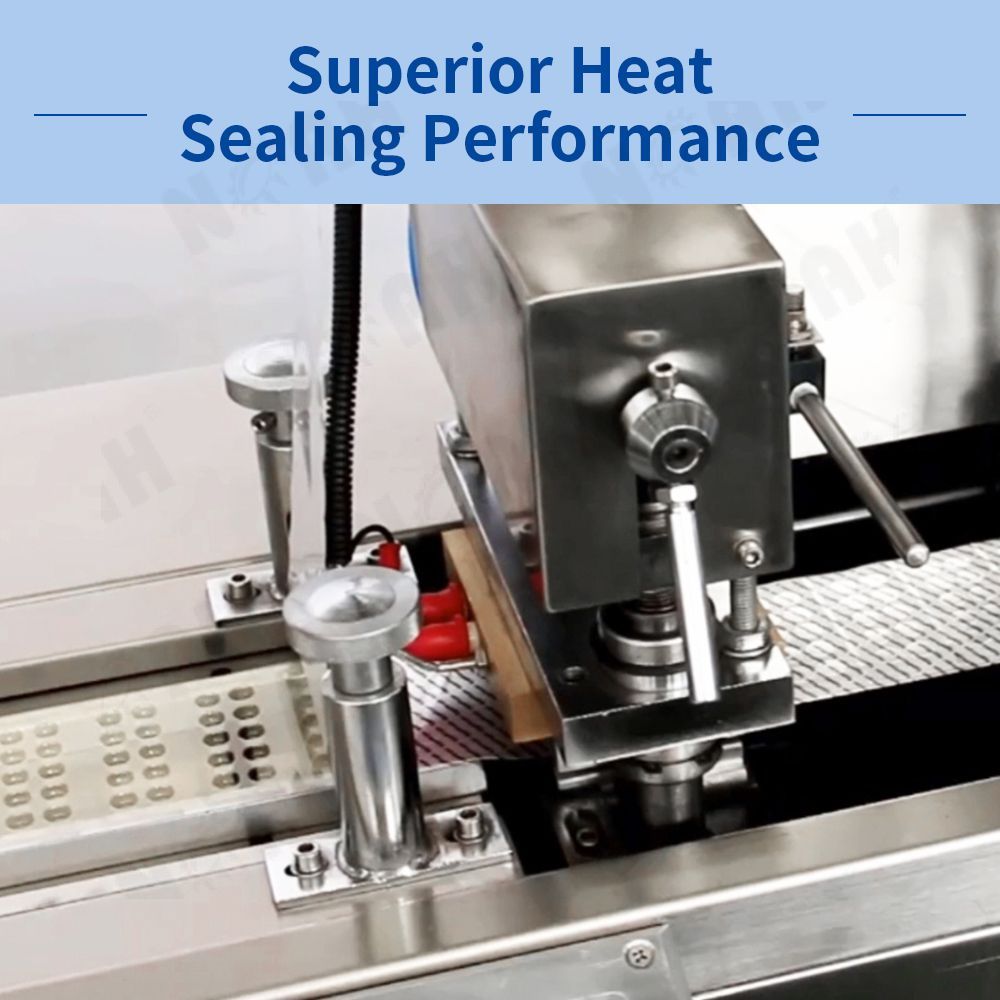

Experience seamless and efficient packaging with our high-performance blister packing machine, delivering secure and professional packaging solutions for a wide range of products.

Download

Download