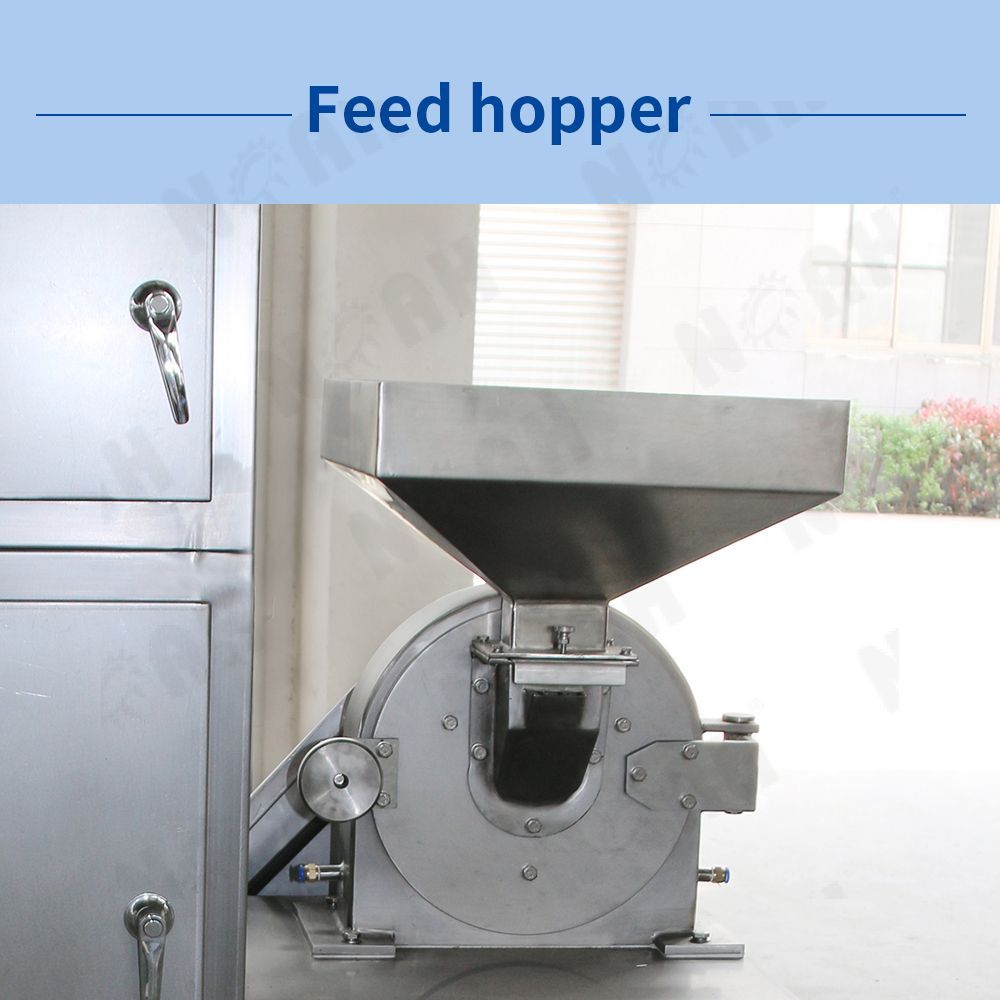

The GF Series Pulverizer Set is designed to provide efficient pulverization and dust collection. It operates using vertical low raw material discharging equipment, ensuring unblocked discharge and preventing powder accumulation. The raw material enters the crushing chamber and is broken by the high-speed rotating fluted discs. The resulting raw material is then obtained through the screening process.

Both the pulverizer and duster components of the machine are made of high-quality stainless steel, ensuring durability and meeting hygiene standards. The inner wall of the housing is processed using superior technology, providing a smooth and level surface that facilitates smooth powder discharge and easy cleaning. The high-speed gear disk with specially welded teeth ensures durability, safety, and reliability during operation. The machine is designed to comply with "GMP" requirements for pharmaceutical applications.

Additionally, the GF Series Pulverizer Set can be customized to include a water cooling device and conveyer screw based on customer needs. This allows for enhanced cooling and material conveying capabilities.

Download

Download