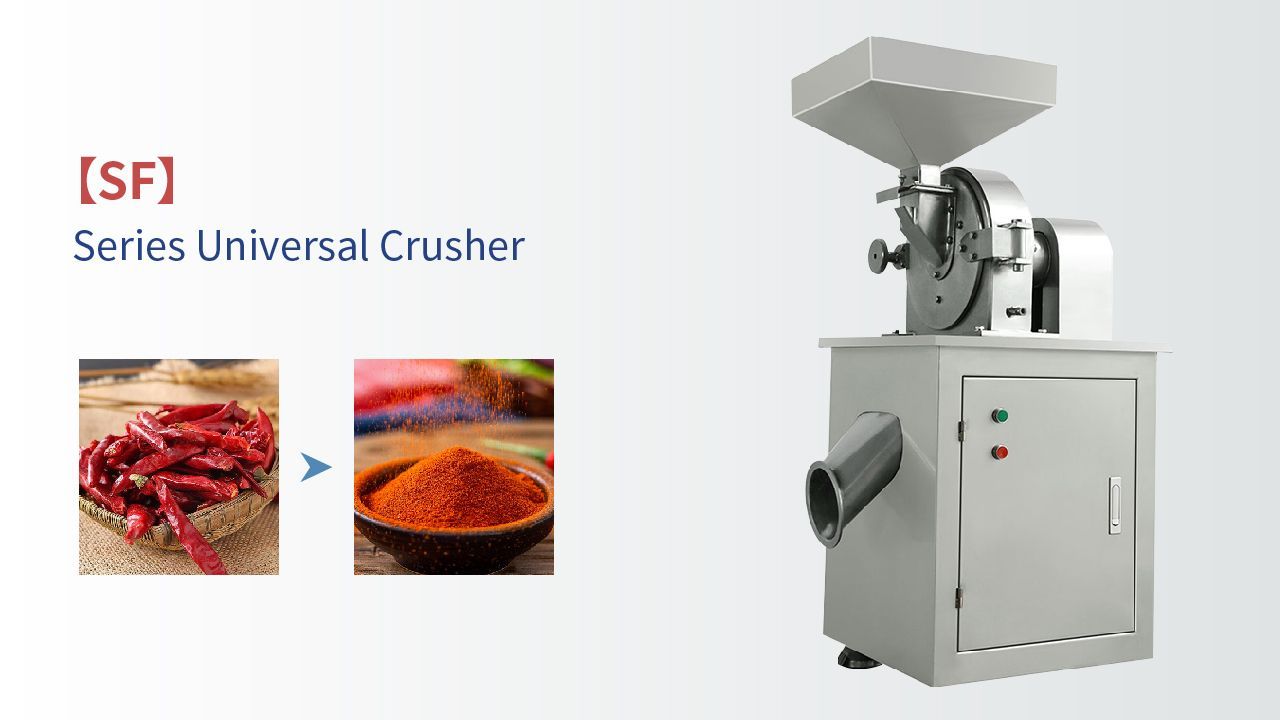

The SF Series Universal Crusher is highly versatile and finds extensive application across diverse industries including pharmaceuticals, chemicals, foodstuffs, and grains. Its adaptability allows it to effectively process a wide range of materials in these industries, making it an essential machine for various crushing needs. Whether in the pharmaceutical sector, chemical industry, food processing, or grain milling, the SF Series Universal Crusher delivers reliable performance and exceptional results.

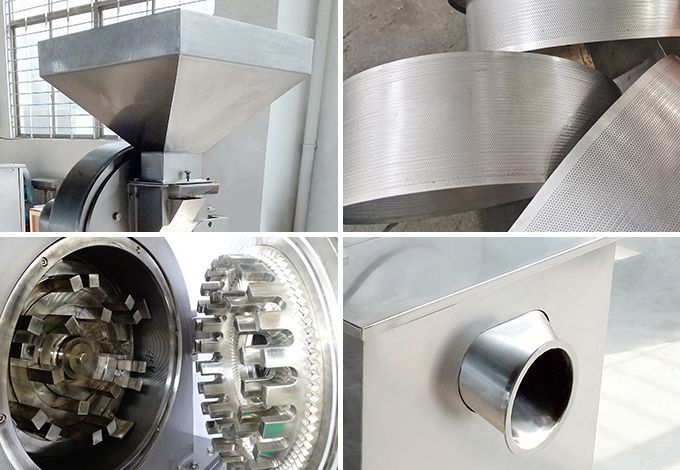

SF Series Universal Crusher

Efficient and precise pulverization for enhanced material processing and production with our advanced pulverizer machine.

Download

Download