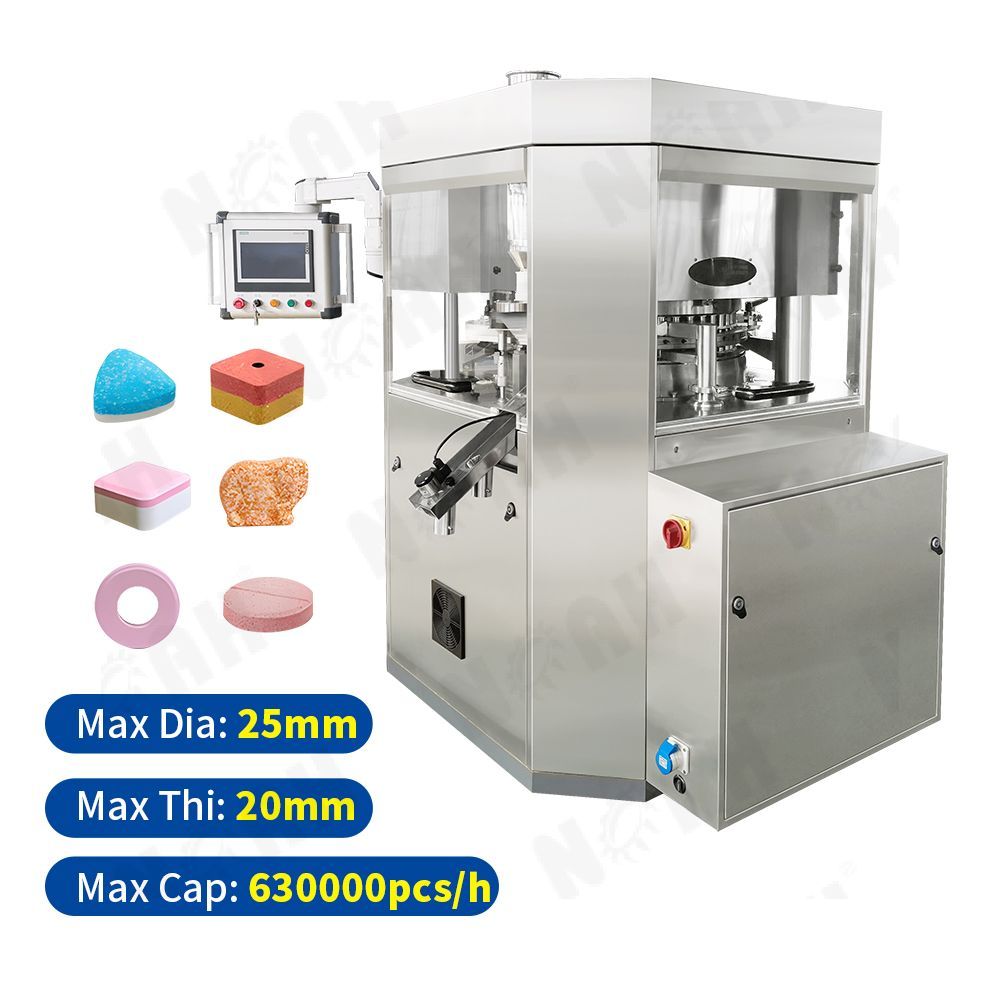

PG800 series high-speed tablet press, with its hygienic design and efficient production capacity, finds wide application across multiple industries. It is suited for manufacturing various oral solid dosage forms like tablets and capsules in the pharmaceutical sector, meeting stringent drug production standards. The machine is also ideal for producing tablets of dietary supplements and nutritional health products, addressing the needs of the health and wellness market. In the cosmetics industry, the PG800 can press tablets containing vitamins or minerals to meet specific requirements. For the chemical industry, it ensures safe storage and precise dosing by pressing chemical compound tablets. Additionally, in the food industry, it produces fast-dissolving or specific-dose compressed food products such as effervescent tablets. Through these diverse applications, the PG800 demonstrates its versatility and reliability, making it preferred equipment for high-volume, high-quality tablet production.

PG800 Series High Speed Tablet Press

Elevate your tablet production with our advanced tablet press solutions.

Download

Download