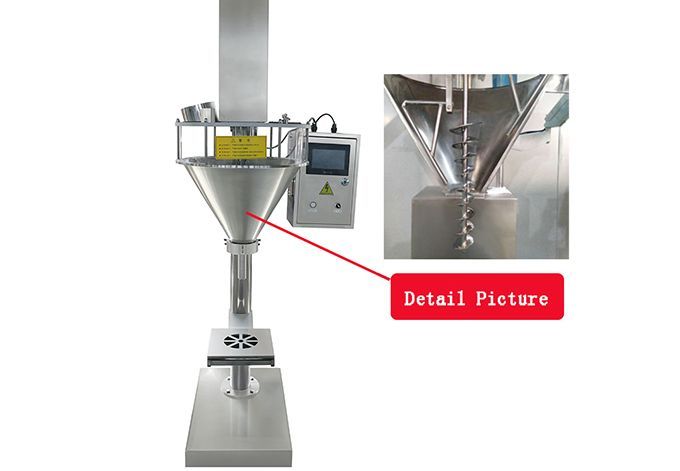

Growing Market Demand: The global market for powdered products, including spices, food ingredients, pharmaceutical powders, and powdered supplements, is experiencing significant growth. The CF-5 Semi-automatic Powder Filler caters to this demand, making it a promising investment option with a positive growth outlook.

Versatile Application Opportunities: The CF-5 machine can handle a wide range of powdered products, providing versatility and opening up multiple market opportunities across various industries. This versatility allows for diverse packaging requirements, expanding the machine's potential customer base.

Efficiency and Accuracy: The CF-5 machine offers efficient and accurate powder filling capabilities. Its precise volumetric filling mechanisms ensure consistent measurements, reducing product waste and maximizing productivity. The machine's semi-automatic operation further enhances efficiency and reduces labor costs.

Flexibility for Container Sizes and Materials: The CF-5 machine is designed to accommodate different container sizes and materials. This flexibility allows businesses to meet various packaging needs and adapt to changing market requirements, enhancing customer satisfaction and expanding market reach.

Cost Savings: Investing in the CF-5 machine can lead to significant cost savings. Its efficient powder filling process reduces product waste and minimizes material costs. Additionally, the machine's semi-automatic operation reduces the need for manual labor, resulting in lower labor expenses.

Improved Product Quality: The CF-5 machine ensures accurate filling of powdered products, maintaining product quality and consistency. This precision reduces the risk of under or overfilling, ensuring customer satisfaction and minimizing product returns or recalls.

Enhanced Branding and Market Positioning: The CF-5 machine offers opportunities for customization, allowing businesses to create visually appealing and branded packaging. This enhances product visibility, differentiation, and market positioning, attracting more customers and potentially increasing market share.

Ease of Operation and Maintenance: The CF-5 machine is designed for user-friendliness and ease of operation. Its straightforward filling process and intuitive controls simplify training requirements and reduce operational complexities. Additionally, the machine's maintenance requirements are typically manageable, minimizing downtime and maximizing productivity.

Long-Term Sustainability: As sustainability becomes increasingly important, the CF-5 machine offers advantages in terms of material efficiency and waste reduction. Its accurate filling mechanisms optimize material usage, minimizing waste generation and aligning with eco-friendly practices.

Return on Investment (ROI): Considering the growing market demand, cost savings, improved product quality, and branding opportunities, the CF-5 Semi-automatic Powder Filler presents a promising investment opportunity. While the specific ROI may vary based on factors such as production volume and market conditions, a well-implemented investment in the CF-5 machine has the potential to generate substantial returns over time.

It is crucial to conduct a comprehensive analysis based on specific business requirements, market conditions, and financial projections before making any investment decisions. Consulting with industry experts and evaluating the machine's performance track record can provide valuable insights for a more accurate investment return analysis.

Download

Download