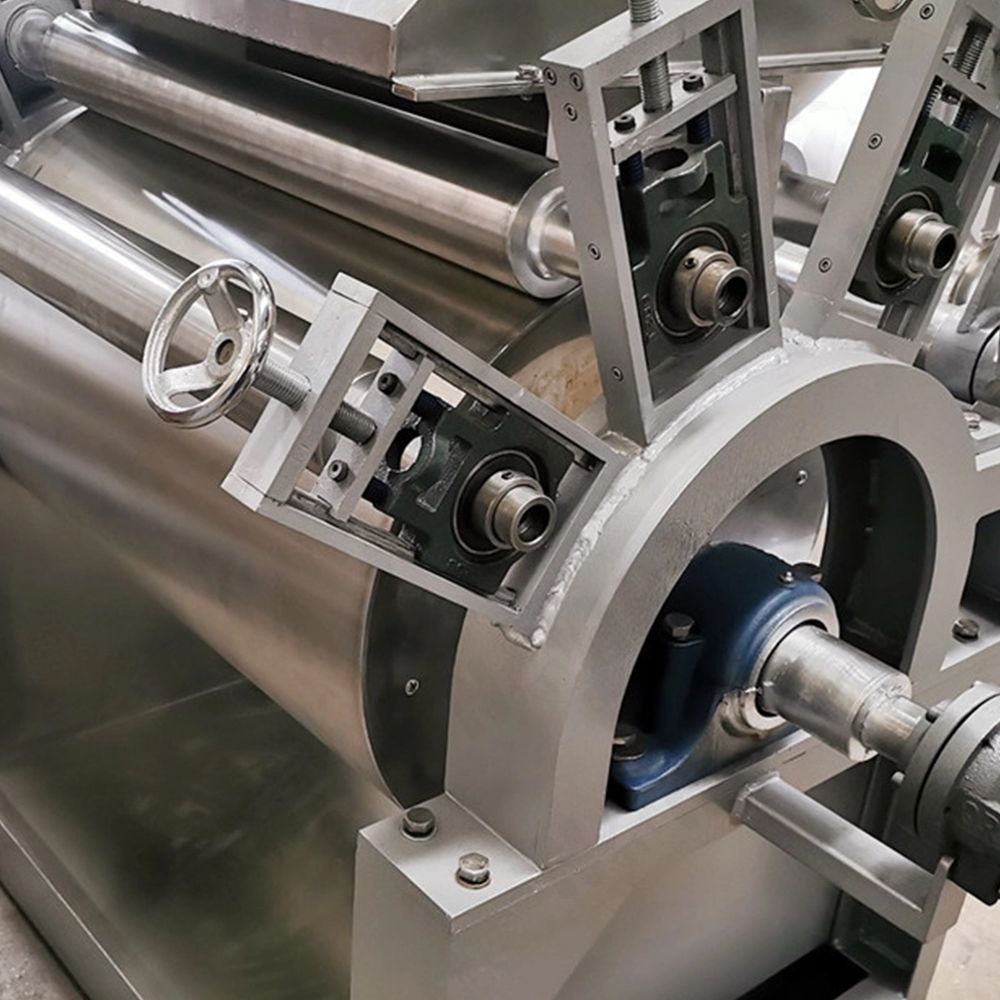

HFG Rotary Scraper Roller Drying Machine is a specialized rotating continuous drying equipment designed for highly efficient and quick drying solutions, particularly suited for liquid materials. By utilizing direct heat conduction, it achieves high thermal efficiency (80%-90%) and ensures that nearly all heat energy is used for evaporating moisture from materials on the roller wall.

This dryer offers flexible operation parameters, allowing adjustments in material density, film thickness, heating medium temperature, and roller speed to accommodate various materials and production requirements. With a typical drying period of only 10 to 15 seconds, it is especially effective for heat-sensitive materials and can operate under reduced pressure when integrated with vacuum devices.

The machine's design promotes fast evaporation, with a thin material film (0.3-1.5 mm) formed on the cylinder wall, enabling an evaporation capacity of up to 70 kg.H2O/m².h. It supports multiple feeding methods—immersion, spray, or grinding assistance—depending on material properties and process needs. Integrated components such as a scraper, spiral conveyor, and adjustable film control ensure uniform material distribution and efficient product removal.

Additionally, the HFG Rotary Scraper Roller Drying Machine supports various heating options, including steam, hot water, or hot oil, providing flexibility in heat source selection. Its ability to operate under reduced pressure conditions enhances safety and product integrity, making it an excellent choice for industries where precise moisture control and thermal sensitivity are critical. This dryer delivers superior thermal performance, adaptable processing, and significant energy savings, ensuring high throughput and productivity.

Download

Download