Filling Range: With a filling capacity ranging from 100 gms to 3000 gms, the machine offers flexibility tailored to the bulk density of the products.

Impressive Output: Capable of producing up to 60 packs per minute, the HDCK's efficiency is influenced by the product's flow properties and the pack size.

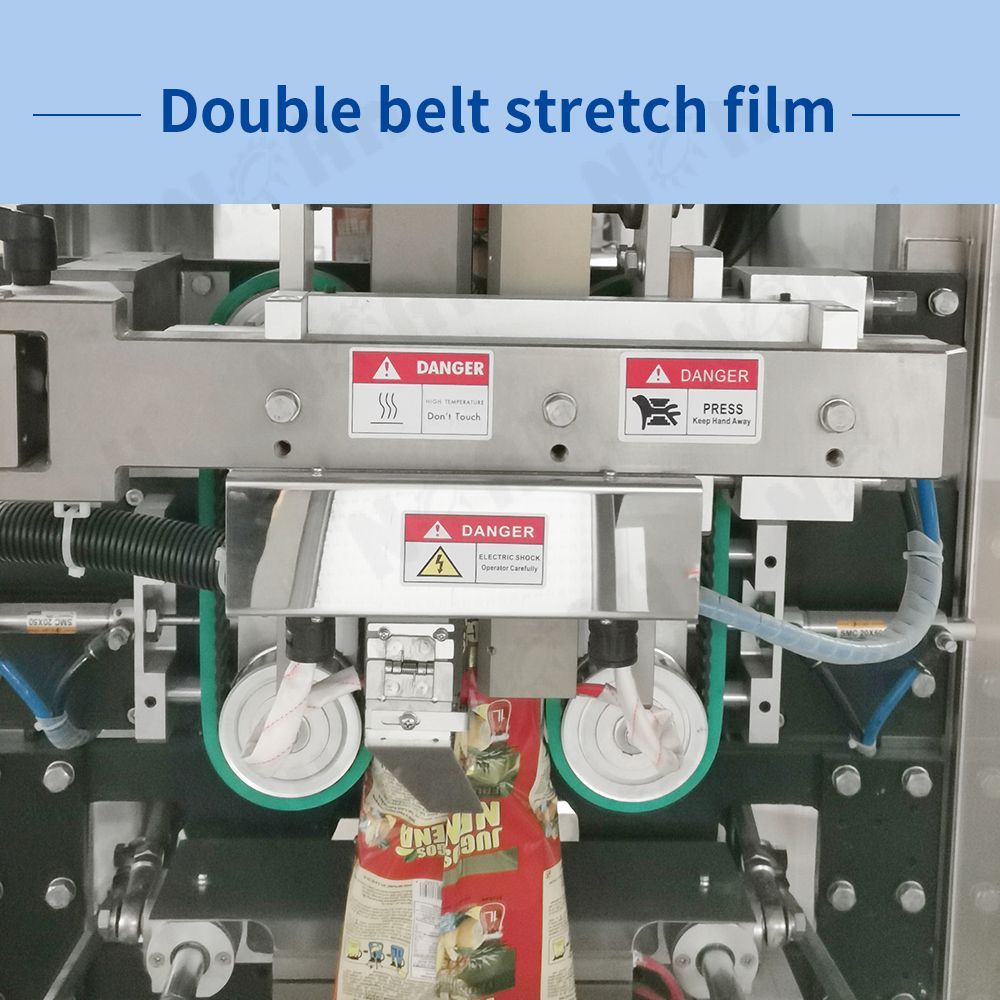

Pack Size Flexibility: Ranging in width from 180 mm to 520 mm , the machine ensures customizable packaging dimensions.

User-Friendly Operation: Equipped with a PLC system and intuitive touch screens, the HDCK guarantees ease of operation for enhanced user experience.

Versatile Compatibility: The machine seamlessly integrates with various filling systems, enhancing its adaptability to diverse packaging needs.

Cost-Effective Maintenance: Designed for simplicity and user-friendliness, the HDCK boasts low maintenance requirements and operating costs, ensuring economical operations.

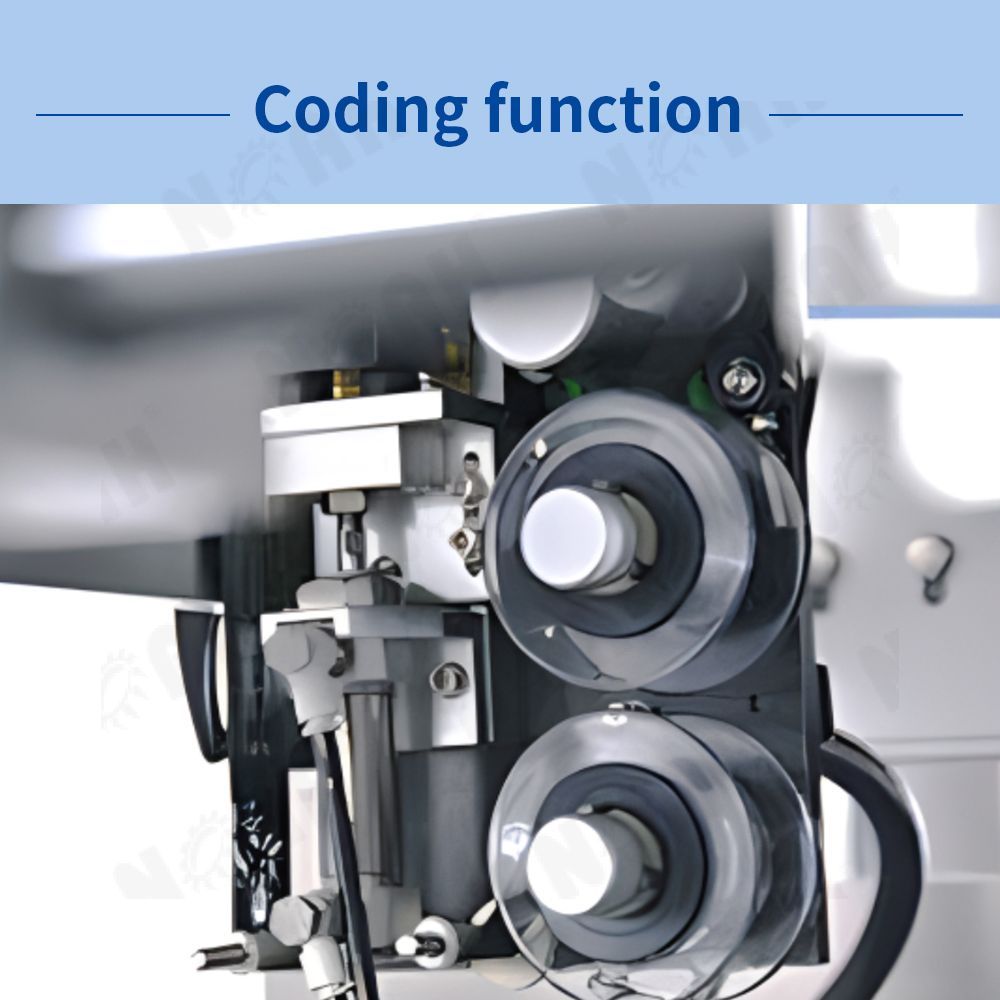

Advanced Functionalities: Featuring barcode and expiration date printing equipment, as well as temperature indicators for sealing surfaces, the HDCK ensures precise and quality packaging.

Diverse Filler Options: With volumetric cup dosing and other filler options, the HDCK caters to a range of product types and packaging requirements with ease.

Download

Download