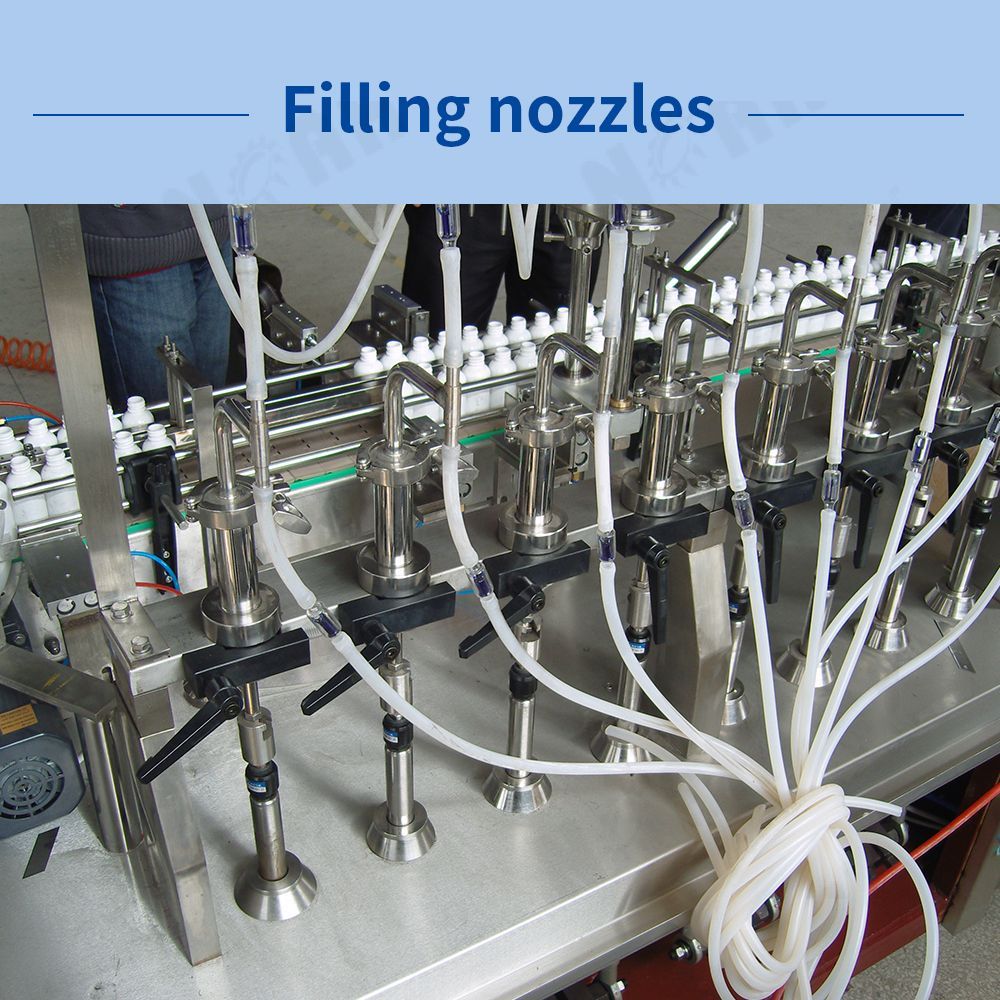

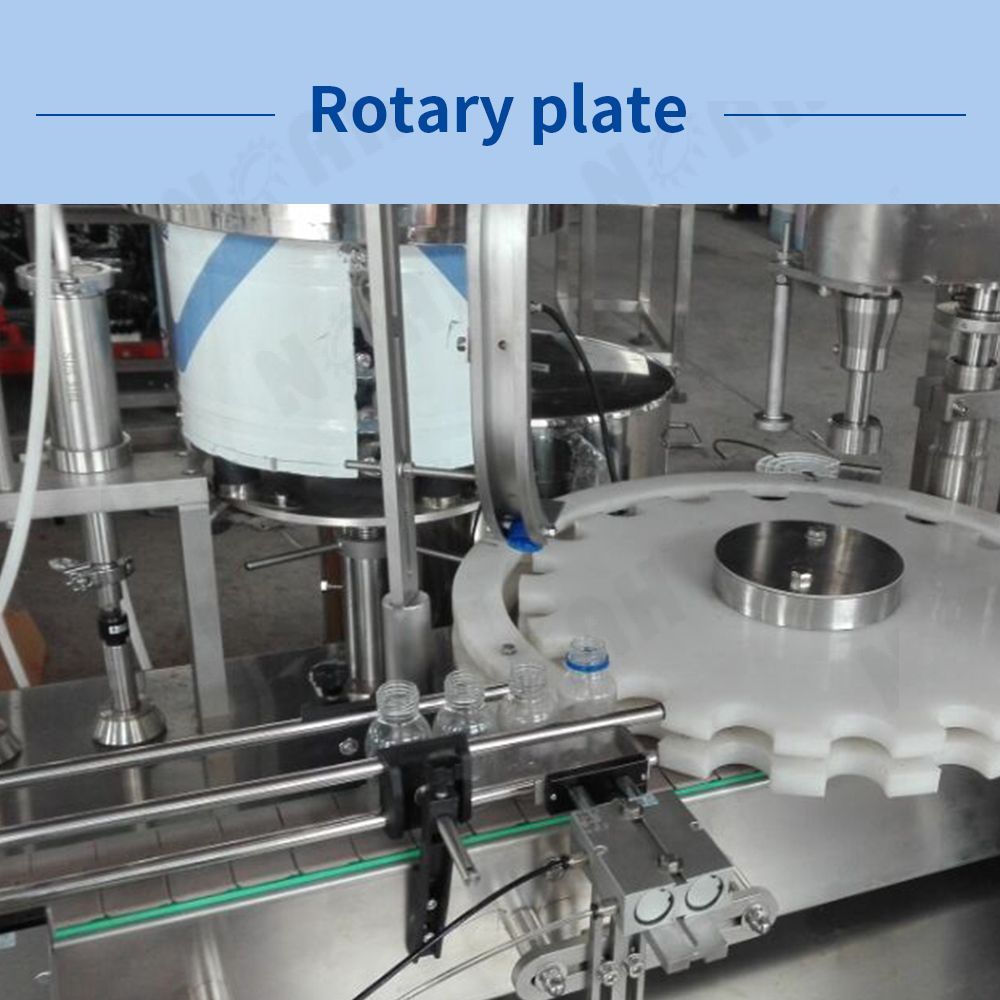

FCM Liquid Filling Machine is widely used in industries requiring precise filling of oral liquid and light liquids with viscosity. It is particularly suitable for the pharmaceutical and healthcare industries for filling oral medications, syrups, tonics, and other similar products. Additionally, it can be utilized in the food and beverage industry for filling light liquid products such as sauces, dressings, and flavored syrups. This machine ensures accurate and efficient filling, improving productivity and product quality.

FCM Liquid Filling Machine

Optimize your pharmaceutical production line with our advanced Automatic Filling Machine, ensuring seamless automation and exceptional accuracy for precise and efficient filling.

Download

Download